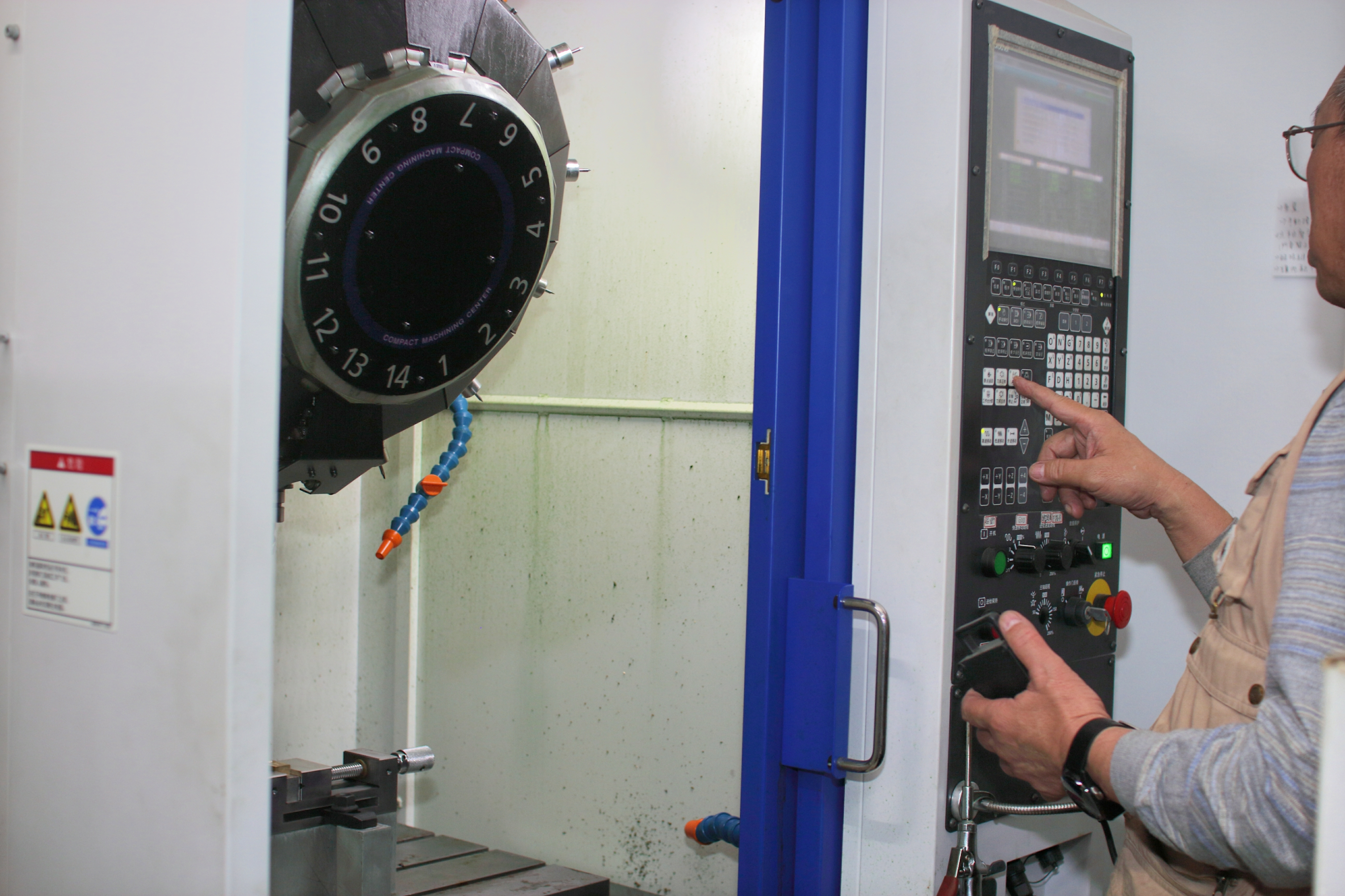

銅模為鉛字的字型母模,呈現為正紋凹型字,鑄成的鉛字則成為反紋凸型字。銅模的製作方式包括衝壓法、雕刻法、電鑄法三種,而日星鑄字行復刻銅模的方式屬於雕刻法,此一運用為日星鑄字行第二代老闆張介冠先生獨力發想復刻銅模之現代方式,傳統方式為手工雕刻成鉛字再電解鑄成銅模,但此電鑄銅模可供鑄鉛字的耐用性較低,且此一工藝技術傳承不多,為加快速度以保存珍貴銅模,張老闆學習專門雕刻模具之電腦數值控制機(CNC)之運用理論及操作,透過電腦軟體將原有鉛字排版打樣修復後轉成電腦使用的字型檔,再經CAM軟體將字體轉檔為NC檔,並反覆進行雕刻模擬,目前先採CNC刻模進行復刻。

張老闆於1980年開始想更新這些銅模,因此思考要不要委託臺灣廠商雕刻銅模,但當時花了幾百萬卻發現文字的重心佈局不佳。1985年左右,張老闆曾尋求工研院合作,用CAM及電腦補刻製造,但因為當時電腦速度太慢,跑一個「國」字的外框「囗」就需要四小時以上,因而停止。1988年日星引進了照相製版及電腦排版,故這段時間放棄重刻銅模。到了2005、2006年因為想將日星轉型,張老闆用 CNC 再重刻這些銅模。

至2020年,張老闆自刻的新銅模約有1000至2000個,質地比以前靠模雕刻的更好,材料是黃銅。

The copper mold is a mother plate of typeset as counter letters, and the typeset will be kerned font. There are three methods for making copper molds: punch, engraving, and electroforming. Ri-Xing reissues the copper mold with engraving and this application is a modern way that Chang has created by himself. The traditional method is hand-engraving the typeset and casting it into the copper mold with electrolytic, even so, this copper mold duration is low and hard to pass down. To speed up the preservation of precious copper molds, Chang has studies the theory and operation of the CNC machine that specializes in engraving molds. He repairs the original typeset and converts it into a font for computer use, moreover, he convert those file into NC with CAM then simulation of engraving repeated. At present, the reissues those cooper molds with CNC machine.

In 1980, Chang wants to renew those copper molds and he was considered to commitment supplier to engraving the copper mold. However, he spends a million dollars and found the copper mold was skewed. Around 1985, Chang has asked the assistance from Industrial Technology Research Institute, using CAM and computer-aided manufacturing to reissue copper mold, but the computer was too slow at that time, for example, they ran "國" and it took more than four hours for the outer frame "口" then they stopped. In 1988, Ri-Xing has brought up photoengraving and computer typesetting and they give up to reissue the copper mold. Until 2005~2006, Chang wants to the transformation of Ri-Xing type foundry and he starts re-engrave these copper mold with a CNC machine.

Now, Chang has around 1,000 to 2,000 new copper molds that he re-engrave by himself, and with better quality of brass.