1888年在美國俄亥俄州辛辛那提市的Henry Barth將手搖鑄字機改良,發明出電動鑄字機。能鑄出鉛字從最大到最小,為144pt到3pt(point),每分鐘可鑄250字,鑄出的字整齊不用手工再做修飾,生產速度大增。

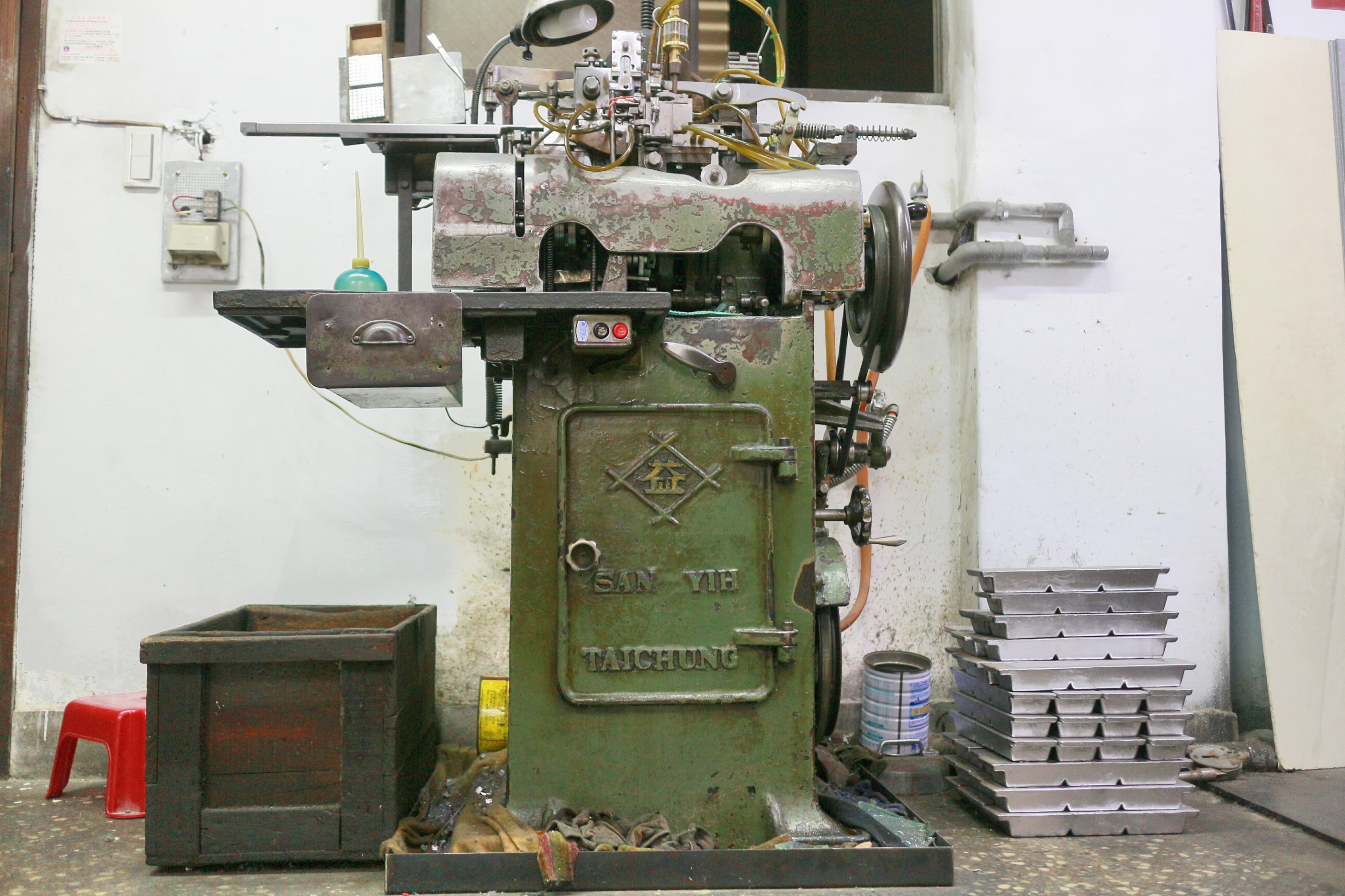

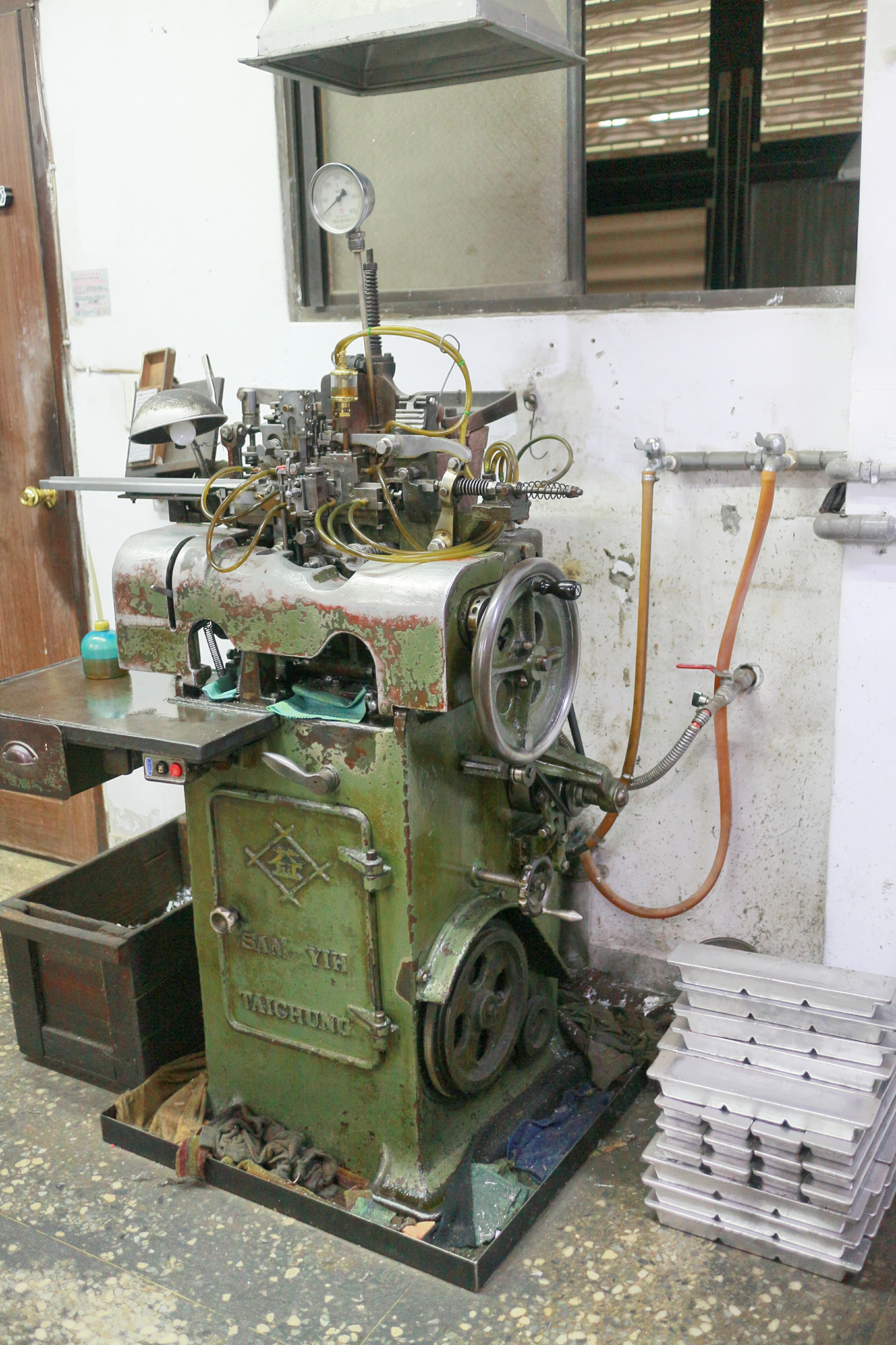

電動鑄字機利用電力作為機器的動力,其主要結構分為鉛鍋與鑄型兩個部份。利用動力將鉛鍋中的鉛液注入鑄型內,透過水冷卻使其瞬間凝固,並透過推桿將字送進鉋台上進行修削的工作。

目前日星鑄字行有7台電動鑄字機,分別鑄初號字(42pt)到六號字(7.875pt)。在1969年日星鑄字型創立時,買一台日本製鑄字機要價約當年的120萬新台幣,那時還是活版印刷的天下,鉛字需求量大,全盛時期日星鑄字行鑄字、檢字師傅加上學徒高達30多人,供應鉛字給200多家客戶,非常忙碌,一年只能休初一。目前台灣也只剩下日星鑄字行持續地以電動鑄字機鑄造鉛字。

In 1888 Henry Barth, of Cincinnati, Ohio, improved the hand swing typecasting machine. Afterwards he invented his own electric typecasting machine which could cast 250 types per minute. The type sizes ranged from 3 point to 144 point. Because people didn’t need to trim these finished types by hand, the speed of casting types increased a lot.

The electric typecasting machine was powered by electricity. Its main structure was divided into two parts: lead melting furnace and mold. The electricity powers the electric typecasting machine to pour lead liquid from the lead melting furnace into the mold, and the mold was cooled off by cold water so lead liquid was solidified into types; next, these types were sent into the thickness planer by a push bar to have these types cut and trimmed.

At the moment, there are seven electric typecasting machines at Ri Xing Type Foundry and each casts certain sized types. The type sizes range from No. 0 to 6. When Ri Xing was founded in 1969, people had to spend one point two million New Taiwan dollars buying a made-in-Japan typecasting machine. At that time, it was the peak of letterpress printing industry and types were in high demand.

In its heyday, Ri Xing used to employ typecasting masters, indexing masters and apprentices and there were 30 of them. Ri Xing offered types to more than two hundred clients and could only take one day off on the first day of every lunar year. So far Ri Xing is the only remaining type foundry which still casts types.