十八世紀歐美鑄字方法,是將字刻於軟鋼之上成為反紋凸型字。經焠火硬化成為鋼衝(steel punch),將鋼衝打入銅塊成為正紋凹型字稱為字模或字母,此為銅模製作的方式之一,接著將銅模安裝於鑄字機內,將熔鉛澆鑄到正紋凹型字的銅質字模,就可形成反紋凸型的鉛字,以供排版印刷使用。

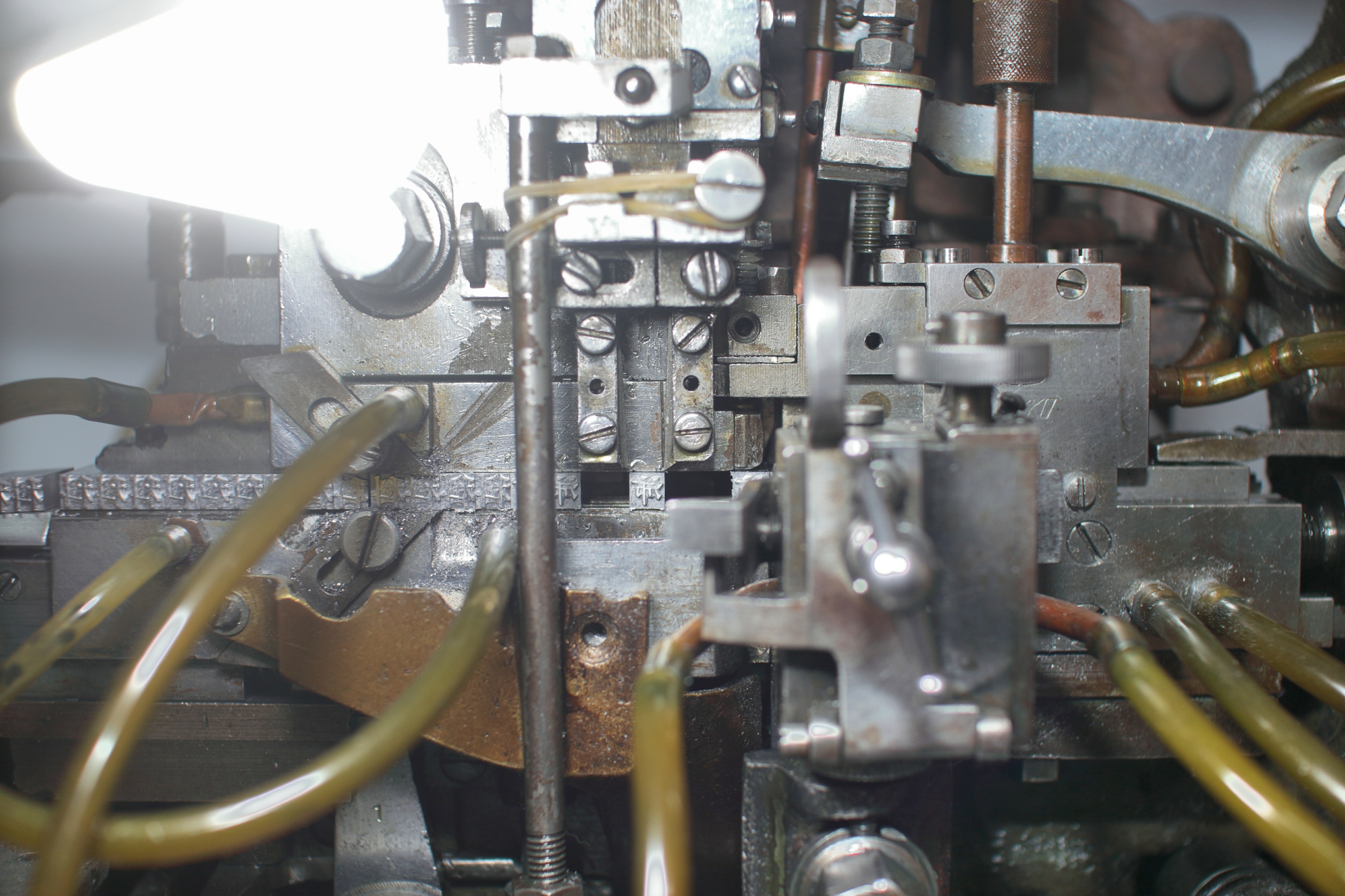

鑄字的流程要先購買由鉛80%、銻15%、錫5%比例製成的鉛條,將鉛條或回收的鉛字倒入鑄字機後面的熔爐,加熱至320至350度,使其熔為液狀。準備好要鑄造的鉛字銅模並裝進鑄字機鑄型內,啟動開關後鉛液自活塞由鉛爐經活塞加壓灌入,經水冷卻後凝固,鑄出鉛字,檢查鉛字是否鑄的好後放入字盒中,待補字員放入字架中。

繁體中文字的鉛字鑄造目前全球應該只剩下台灣的日星鑄字行的機器依舊運轉著,當全台最大的中南鑄字行於2001年關閉後,日星張介冠老闆警覺到活版鉛字有可能真的在台灣消失,因此他下定決心將整間鑄字行保留下來,作為台灣活字印刷文化的見證。只是鉛字的鑄造不再只是供應印刷廠,目前日星鑄字行朝文創商品開發與創新客製、活版印刷教育推廣來發展。2016年日星鑄字行以集資的方式啟動「字體銅模修復計畫」,逐一修復因數十年使用而有缺損的銅模並重新鑄造,希望能保留住台灣活字鑄造的種子。

In the eighteenth century in the Western world, letters were engraved on the mild steel and letters as counter letters. After the mild steel was hardened, steel punches were formed. These steel punches with counter letters were pressed into the copper block and there were copper molds with letters. This was one of the ways that workers made copper molds.

Afterwards workers placed the copper mold in a typecasting machine and the lead liquid was poured into the copper mold to cast counter types for typesetting and printing.

Before casting types, workers need to buy the lead alloy that consists of approximately 80% of lead, 15% of antimony, and 5% of tin. Next, they put the lead alloy or recycled types into the lead melting furnace behind a typecasting machine. The lead alloy or recycled types are heated to around 320~350 degrees Celsius, the lead liquid is made and people place a chosen copper mold in a typecasting machine. After the typecasting machine is powered on, the lead liquid is poured from the lead melting furnace into the copper mold by piston pressurization. After the copper mold is cooled off by cold water, the lead liquid is solidified into types. At that time, types are inspected by typecasting masters. If types are in perfect condition, they will be placed onto typeset shelves.

Ri Xing Type Foundry is the only remaining foundry which still makes traditional Chinese characters in the world. In 2001, Chung NaN Type Foundry, the biggest type foundry in Taiwan, was out of business. After that, the owner of Ri Xing, Chang Chieh-kuan, was conscious that types will somehow disappear in Taiwan. So he decided to preserve Ri Xing and let it become a witness of the letterpress printing culture. But Ri Xing no longer offers types to printing plants. Right now Ri Xing focuses on developing cultural and creative products, providing customized products and promoting letterpress printing related education.

In 2016, in order to preserve the letterpress printing culture, Ri Xing raised funds to launch its own “restoration and preservation plan” to mend and recast these copper molds which were either partly or wholly worn.