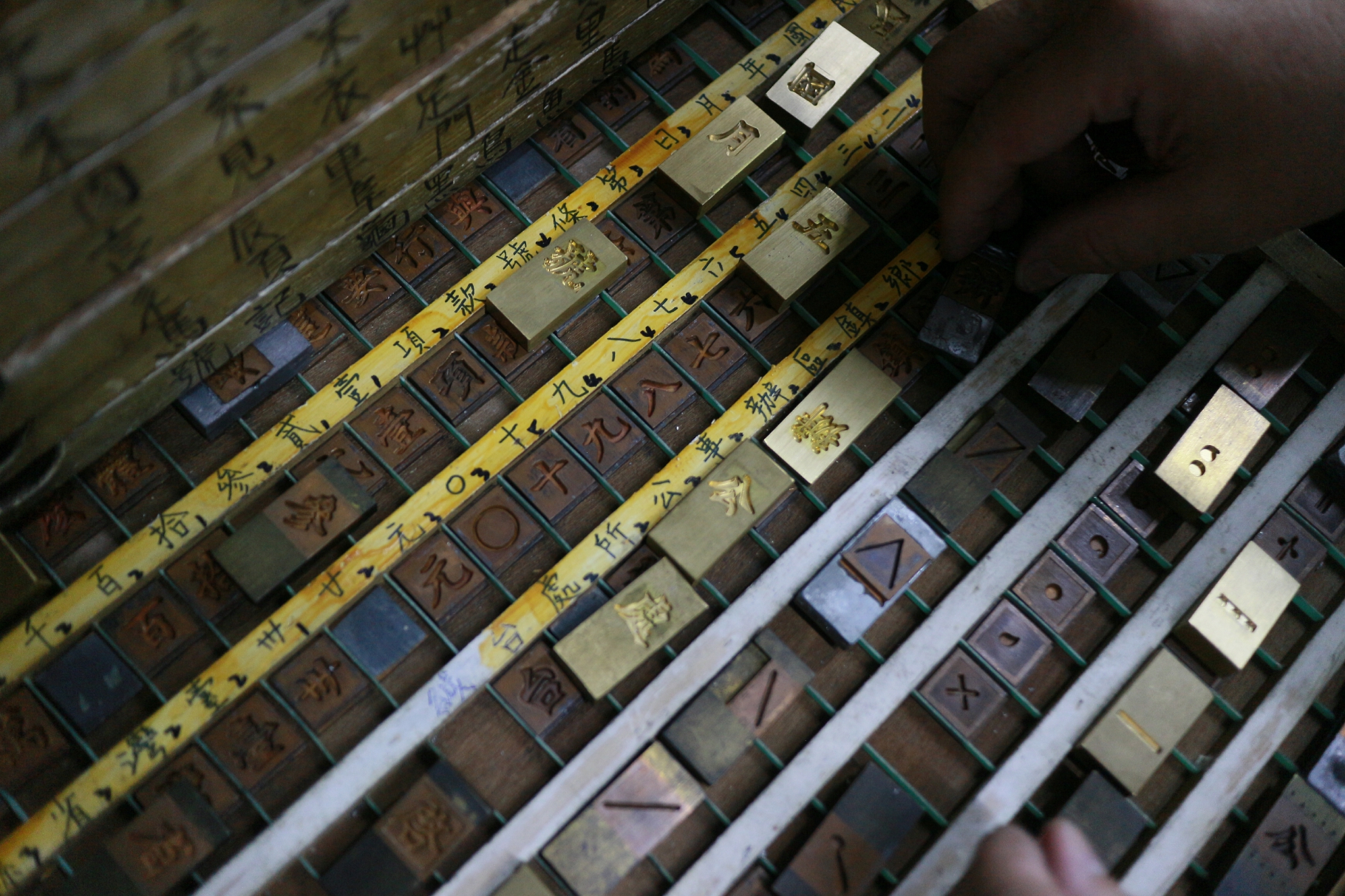

日星鑄字行大部份的銅模是開業時就有了,1972、1973年新增一號楷書。聯合報於1982年數位化後,將初號宋體銅模及兩台鑄字機販售給日星鑄字行。

銅模分為許多種。全部銅製的是「標準銅模」,用電鍍的方式製作,使紅銅附著到一定程度後(約半個至一個月)再一塊塊拔下來,嵌到黃銅載台裡。因為無法完全密合,所以要再用亞鋅(排版所剩的廢料)填滿。二戰時,黃銅都送往日本本土,於是使用亞鋅鉛做載台。這種材料較為鬆散,也需要常用油潤滑保養。後來因為產業結構改變,活字印刷式微,所以有陣子疏於保養,許多銅模脆化不能使用,而日星這類的銅模又佔了60%左右,所以銅模需要保養、重製。較白的銅模是因為它們的鋁含量較高。

日星鑄字行的三號黑體字是1981年左右開始以靠模雕刻的方式製造,再以靠模機依比例雕刻的。這種機器在1855年由美國人設計,製成的銅模質地比電解的好,耐鑄量是兩百萬以上,價格與只能二十萬鑄量的電鍍銅膜差了五至六倍。

日星鑄字行第二代老闆張介冠於1981年的時候,開始想保留這些銅模,因此思考要不要委託臺灣廠商雕刻五號楷書的銅模,但當時花了幾百萬卻發現文字歪斜重心佈局不佳,以為是銅模沒有鑄好,經過兩三年的要求依舊如此,才發現是銅模的字本身歪斜問題,才開始學習字型相關的知識。1985年左右,張老闆曾尋求工研院協助,用CAM及電腦輔助製造,用小型CNC雕刻機想要重刻銅模;但因為當時電腦速度太慢,跑一個「國」字的外框「囗」就需要四小時以上,因而停止。1988年日星引進了照相製版及電腦排版,故這段時間放棄重刻銅模。到了2005、2006年因為想將日星轉型,張老闆用CNC再重刻這些銅模,材料改用質量較好的黃銅。

The most copper mold of Ri-Xing type foundry was available when they started the business. They got size 1 of Kaiti in 1972~1973. After the digitization of the United Daily News in 1982, they sold size 0 of Songti and two typecasting machines to Ri-Xing.

There are many kinds of copper mold. "Standard copper mold" is made by copper with electroplating the red copper to adhere it (it will take half to one month) then pulled out one by one and embedded in the brass carrier. Because it can't be completely sealed, it must be filled with zinc that is the waste leftover from typesetting. During World War II, all brass was sent to Japan, and zinc-lead was used as the carrier. This material is loose and requires lubrication frequently. Due to the movable type printing industrial structure changed and the decline of this industrial. Therefore, neglected maintenance and many copper molds became brittle and could not be used. Ri-Xing has almost 60% copper mold as explained above. Hence, copper mold needed maintenance and remanufacturing. The whiter copper molds are due to their higher aluminum content.

Since 1981, the size 3 of heiti was engraving with the copying machine tool. The Americans designed this machine in 1855, and the product quality is better than electrolytic one. The cast resistance is more than two million and the price is also five to six times the difference from the electroplating copper mold with only 200,000 casts. Chang wants to keep those copper molds and he committed the supplier to engraving the copper mold of size 5 Kaiti. However, he spends million dollars and found the copper mold was skewed at the beginning and he thought the copper mold was not cast well. After two to three years, and still, the same problem then finding copper mold, itself, were skewed, then he starts to studies the knowledge of font.

Around 1985, Chang has asked the assistance from Industrial Technology Research Institute, using CAM and computer-aided manufacturing to reissue copper mold, but the computer was too slow at that time, for example, they ran “國” and it took more than four hours for the outer frame ”口” then they stopped. In 1988, Ri-Xing has brought up photoengraving and computer typesetting and they give up to reissue the copper mold. Until 2005~2006, Chang wants to the transformation of Ri-Xing and he starts re-engrave these copper mold with a CNC machine and changed the material into a better quality of brass.